Cellular CNC Machining is not a new concept but it has had a massive impact on the manufacturing industry. Cellular manufacturing is a concept from Lean manufacturing, created to optimize the production of families of parts and improve the efficiency of a machine shop. Superior Thread Rolling employs the cellular method in our CNC machine shop with great success, allowing us to provide our customers with an optimum balance of pricing, quality, and performance.

A quick introduction to cellular manufacturing

Cellular CNC machining or cellular manufacturing (depending on the particular application) is a method for organizing production on the floor. In this method, all of the workstations, equipment, parts bins, tools, and other resources are physically organized in a way that accommodates an optimized flow of production from one piece of equipment to the next. This enables parts to move through each step of production as quickly and efficiently as possible, minimizing waste and logistical effort across the cells

The goal of cellular machining is to organize everything in a way that optimizes the production of a part family, groups of parts that are similar enough to each other that the changeover between them is minimized. In order to execute cellular manufacturing around families of parts, this strategy requires the alignment of everyone from the CEO and sales all the way down to the production floor. As a result, the manufacturing cells are put together according to the capabilities and capacities necessary for these part families.

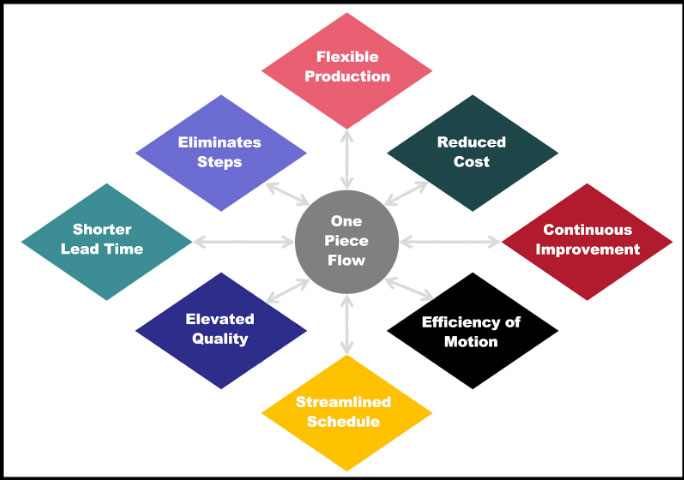

Single piece flow

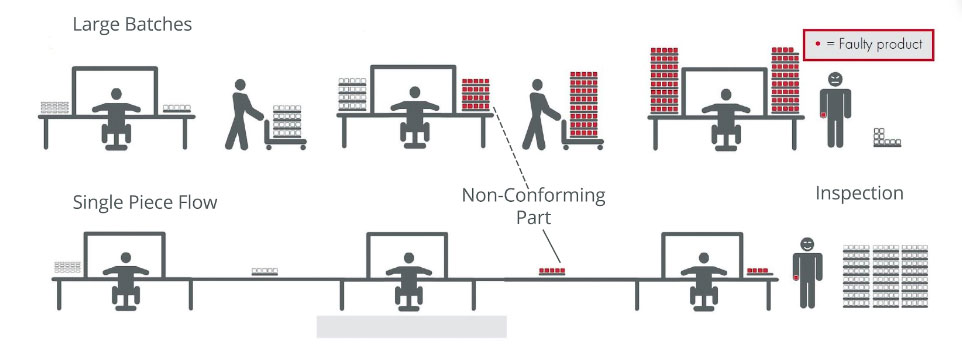

One of the key aspects of cellular CNC machining is a ‘single piece’ flow of parts. Rather than processing a batch of parts in a workstation simultaneously, these Lean machining cells are designed to accommodate parts through each machine one at a time. This enables quick production of a variety of products, or in other words, part families. This helps prevent the queuing up of parts between tool swapping, and promotes a much more efficient process. It also promotes improved quality across part batches, as the operators can find any defects or problems without affecting the entire production batch. This is especially important for applications where tight tolerances are critical, such as in Aerospace equipment.

Single piece flow is not the best way for every shop. Manufacturing projects come in a wide range of production volumes, from single-part projects and prototyping all the way up to high volume factory production. However, most CNC machine shops live in the middle of that spectrum, making anywhere from a few parts to a few thousand at a time, such as in Aerospace manufacturing. In this middle area of production volume, cellular machining has proven to be the most efficient method, allowing shops to optimize not only their part mixes, but also their shop’s efficiency.

Cellular Machining at Superior Thread Rolling

Superior Thread utilizes cellular CNC machining, combining our Lean manufacturing systems into efficient and economical cells for different families of parts. From large fuse pins to a variety of small bolts and fasteners, we use these cells to supply quality components to our partners in Aerospace manufacturing.

Check out all of our different CNC machining cells here.

If you’re interested in working with Superior Thread Rolling, check out our website to learn more or to contact us!